In spite of these combined effects only tensile capacity is currently considered in design and testing. Adding to this design oversight tensile capacity isnt the weakest performance link.

Ex ample of design parameters are bolt length bolt spacing tensile stre ngth.

. As shown in the photo rock bolts may be used to support wire mesh but this is usually a small part of their function. YouTube Send Inquiry. Soft-rock mining refers to the excavation of softer minerals.

Rock bolts and prestressed anchors were used as reinforcements. The design considerations of bolts in Part 7 Part 9 10 and Part 16 Chapter J. In this movie we explain how to define rockbolts in the Tunnel Designer available since PLAXIS 2D 2016.

1 install rock bolts 2 embed prestressed anchors and 3 place shotcrete. Effective Area of Anchor Bolts. Other parts of the manual cover more complex connections such as flexible moment connections Part11 fully restrained moment connections Part 12 bracing and truss connections Part 13 column splices Part 14 hanger connections bracket plates and crane-rail connections Part 15.

It was carried out for MINE 6002 term project Dr. Bolt-action lever-action pump-action and semi-automatic rifles are known as repeating. What can I do for you.

Anchor 0226 in² 1458 mm². Full-column slowfast-resin combination bolts dual resin system. Two sleeves 13 14 have been pressed onto the ends of.

Bolts and ground anchors after Windsor and Thompson 1997 There are eight types of roof bolts used in the South African coal mining industry. D epth of anchor bars in rock mass Actual force in each anchor. For both design methods the anchor bolt net area used to determine the design values presented in this TEK are taken equal to the following which account for the reduction in area due to the presence of the anchor threading.

Unlike common anchor bolts rock bolts can become seized throughout their length by small shears in the rock mass so. Trenchless methods of pipeline installation such as microtunneling and pipe jacking require excavating launch and exit pits for workers to operate. Shear capacity on.

A natural pressure arch is formed in the rock at a certain distance behind the tunnel wall. The rock bolt and prestressed anchor. China Rock Bolt Design Example Manufacture Visit Here to Find the Rock Bolt Design Example That You are Searching for.

These ratings are summed to give a value of RMR. Unless rock has been severely weathered it will usually allow for an open hole to be drilled without any risk of collapse. Rock bolt design example Ditulis Bryan Mcclure Sabtu 19 Maret 2022 Tulis Komentar Edit.

Rock Bolt Design Example We always continually provide you with the most conscientious customer service and the widest variety of designs and styles with finest materials. Once the assembly is in place a sharp pull on the end of the bolt will seat the. In the following four constitutive models developed for the design of rock-bolt system based on analytical methods will be discussed.

In rock slopes noise parameters are joint and rock properties which are inherently variable and cannot be controlled. When tension is applied to the tendon the tapered plug within the shell forces the leaves to move outwards thus wedging them against the walls of. DYWIDAG Threadbar is used to bond unstable rock to stable sections beyond the rockfaceproviding both tensile and shear loading capacity.

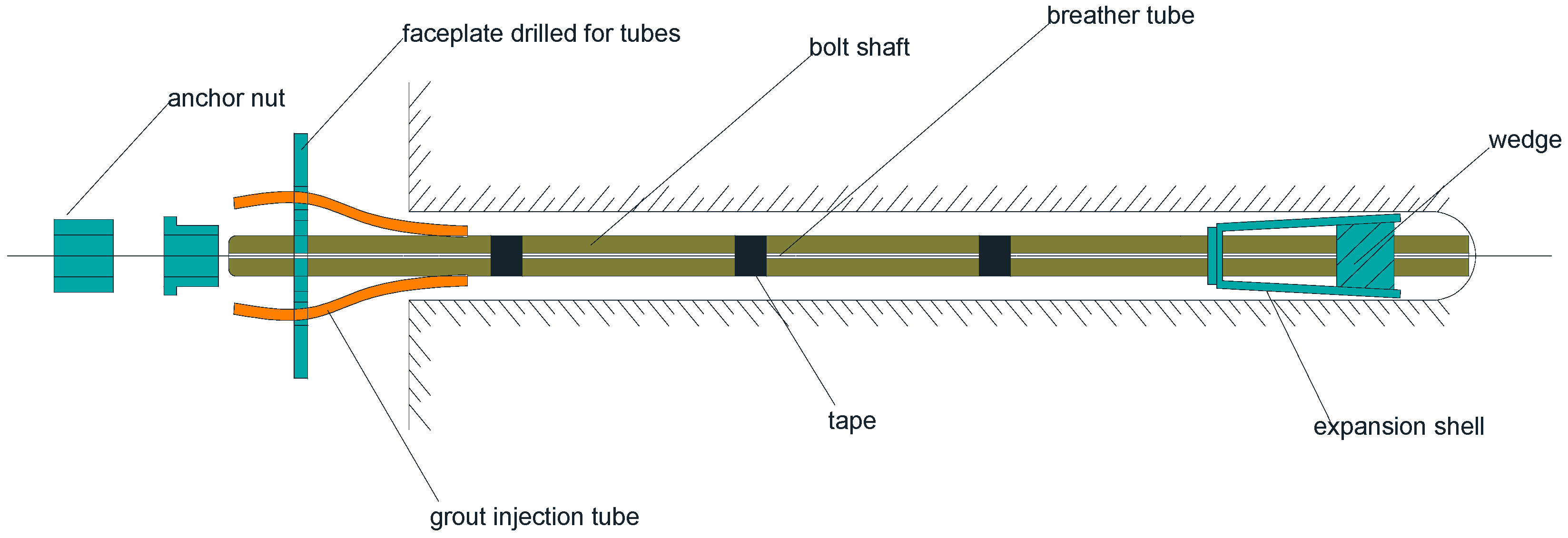

Rock bolts rockbolts reinforcement PLAXIS PLAXIS VIP VIP Tunnel rock PLAXIS 2D tunnel designer Created by Micha van der Sloot. Rock Bolts are mechanically point anchored within the rock using 3 leaf bail-type expansion shells attached to the inserted end of the bolt. These efforts include the availability of customized designs with speed and dispatch for Rock Bolt Design Example 47mm Strata Bolt Split Set Washer Manufacturer Split Set W-Strap Screen Mesh.

2 Design methods 3 Rock slopes 4 Rock foundations Site investigation techniques laboratory tests mathematical and physical models are all examined in the light of their relevance to engineering design. For example consider the design of the tank for uplift. In newer versions of PLAXIS the Rock bolts option inside the Tunnel Designer is now called Reinforcements.

Rockbolts should be long. Another example of design elegance and simplicity is the utilization of a single set of cylinders which means there is less potential problems to occur. Threaded end of the bolt and the entire assembly is inserted into the hole that has been drilled to receive the rockbolt.

CHAPTER 15 Rock Slope Design NYSDOT Geotechnical Page 15-5 January 14 2015 Design Manual The detailed requirements for the design of rock cuts are provided in FHWA-HI-99-007 Rock Slopes. How rock bolts work. Rock bolts are long bolts that anchor or support excavation by penetrating deep into the stronger portion of the rock and holding fast.

Expansion shells are supplied screwed to the end of the rock tendon and are inserted into the hole. The rock bolts were installed in a pattern of a 2 2 m grid over the entire arch and a 3 2 m grid on the two sidewalls. Reinforcement in each stage was conducted in the following sequence.

The original diameter can for example be 41 mm and the diameter after deformation can be 28 mm. The length of the hole should be at least 100 mm longer than the bolt otherwise the bail will be dislodged by being forced against the end of the hole. Anchor 0142 in² 916 mm² ⅝ in.

A ctual force in each anchor Unbalanced uplift pressure No of anchors required per unit area. Once the rock bolt is anchored a compression force is set up into the surrounding rock. The use of the factor of safety as a design index is discussed and an assessment is given of the most practical approach to designing rock slopes and foundations.

This video demonstrates how rock bolts work to stabilize fractured ground jointed rock mass around tunnels. HDR-25 Shipping Assembly complete with an AR6525 coneshell anchor HDR Site Assembly. The following equations are used in the design of rock anchors.

Rock bolts work by knitting the rock mass together sufficiently before it can move enough to loosen and fail by unraveling piece by piece. Energy-absorbing rockbolts are preferred in the case of high in situ stresses. Rock bolts are generally exposed to a combination of shear bending and tension that can cause the bolt to deform with increasing joint displacement potentially leading to failure.

Rock bolts are used in. In is of great importance to utterly acquaint with those models involving the rock-bolts rock mass interaction.

A A Frictional Rock Bolt B An Expansion Shell Rock Bolt 8 Download Scientific Diagram

Components Of An Expansion Shell Type Mechanically Anchored Rock Bolt Download Scientific Diagram

Sensors Free Full Text A Review Of Rock Bolt Monitoring Using Smart Sensors Html

Sensors Free Full Text A Review Of Rock Bolt Monitoring Using Smart Sensors Html

Sensors Free Full Text A Review Of Rock Bolt Monitoring Using Smart Sensors Html

0 comments

Post a Comment